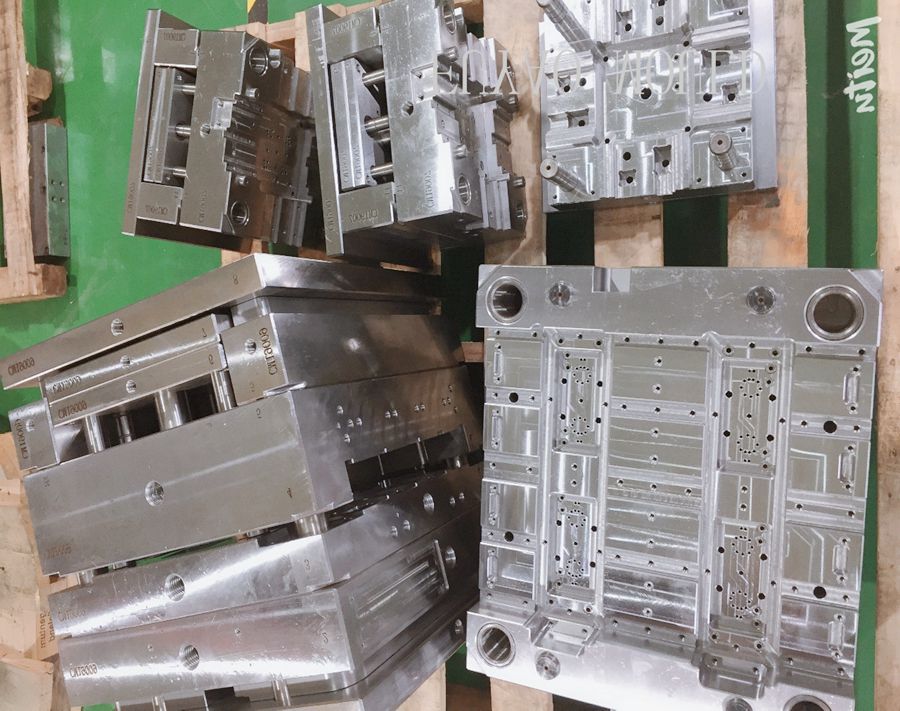

Key Words: precision automotive connector plastic mould/tooling manufacturer

Phone: +86 769 81886557

E-mail: linda@fuyaomould.com

Compared with other moulds, injection moulds are more complex and precise in structure and have higher requirements for operating and maintaining products. Therefore, in the entire production process, the use of positive solutions and meticulous maintenance, maintenance is to maintain the normal production of enterprises and improve the enterprise Benefits are of great significance.

1. select the appropriate moulding equipment, when selecting the injection machine, it should be based on the maximum injection volume, the effective distance of the tie rod, the mould installation size on the template, the maximum mould thickness, the minimum mould thickness, the template stroke, ejection method, ejection stroke, injection pressure, Clamping force and other items are checked, and only after sufficient requirements can be used. Reasonable determination of process conditions is also one of the contents of the correct use of the mould, too much clamping force, too high injection pressure, too fast injection rate, too high mould temperature, etc. will damage the service life of the mould.

2. After the mould is installed on the injection machine, the empty mould operation must be performed first. Observe whether the operation of each part is flexible, whether there is any abnormal phenomenon, ejection stroke, whether the opening stroke is in place, whether the parting surface is tightly matched when the mould is closed, and whether the screw of the pressure plate is tightened.

3. When using the mould, keep the normal temperature and work at normal temperature to prolong the service life of the mould.

4. the sliding parts on the mould, such as guideposts, return pins, pushrods, cores, etc., should be observed at any time, checked regularly, scrubbed and filled with grease, especially when the temperature is high in summer, add at least two per shift Secondary oil to ensure that these sliders move flexibly and prevent tight bites.

5. before each clamping, you should pay attention to whether the cavity is cleaned, and no residual products or any other foreign objects are allowed. When cleaning, do not use hard tools to prevent damage to the cavity surface.